+86 10 85323436

+86 10 85323436 ![]() 2022-07-08

2022-07-08 ![]() 5909

5909

Introduction:

Our solution can fully treat mixed city waste (MSW) but even better treat the new separated collected household kitchen waste in Chinese cities (OFMSW). Compared to other treatments mechanical biological treatment (MBT) plant is specially designed for Chinese waste. Starting with our pretreatment which has some special equipment which can more effectively separate the waste into different parts. The biggest part is the separated is the wet food waste, we can convert to more renewable energy 100-150³/t of biogas. And a high burning value Green coal 2500 Kcal/kg.

As a result, waste become a valuable source of green energy, a process with no smell or air pollution can be close to the city saving money and pollution from too high transportation cost in China. Part of this savings can go into higher land cost and a better process. The biogas can be utilized as fuel for waste collection. Our solution closes the environmental circle and +700% produce more CO2 neutral renewable energy from every ton of city waste. This is the 1st step into modern and cleaner waste treatment in China and future “Urban Mining”.

Depending on the budget or future market value for recycling materials, our clients can add additional sorting lines to clean separate certain plastic in different colours (PET, PE, PC, PVC…) we have the best working technology using in our port fort folio. Like special NIR optical infrared, washing and extrusion technology for plastic recycling to clean plastic flakes or resin.

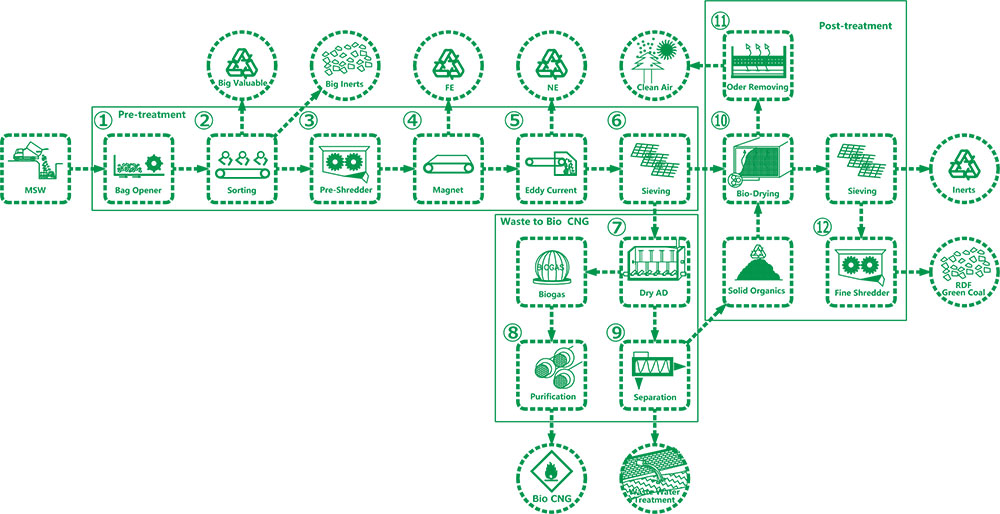

Process Flow Description:

This flow above flow chart is only for your reference. The finest solution depending on the specific waste input MSW or OFMSW and utilization of the output materials requirements at the local area.

Pre-Treatment

1.Our bag opener can open bag in bag waste and spread the waste onto a sorting belt.

2.At the sorting station people and in the future robots remove big impurities (stones and recyclable parts to protect the succeeding equipment.

3.A special big size crusher cuts the waste to<250mm to prepare the waste well for the following sieving process.

4.Ferrous metals is separated out by magnets (iron, steel).

5.Our IFE ballistic separator reaches very good results to remove nonferrous metals like alloys, copper…and some electronic waste).

6.Our special IFE flat screen can sort out best results with complicated Chinese wet waste, to separate the light materials parts (2D+3D plastic, paper, close with high burning value) “overflow”, from the heavy material (waste food (55%), stones, glass, waste water) “underflow”.

Waste to Bio-CNG

7.The wet heavy organic “underflow” can be processed directly including impurities in our special KOMPOGAS dry fermentation plug flow digesters. The only process with no sedimentation, highest organic load/m³ tank volume. Able to produce high amount of biogas 100-150m³/t from complicated waste in very small tank volume.

8.The captured biogas is stored and can be upgraded by our special EVONIK membrane technology (less 1% methane loss) to produce Chinese standard “Bio-CNG” which can replace fossil fuel CNG for public transport or replace all fossil fuel for waste collection.

9.The 95% degraded organic material out of the Dry digester will be dewatered into liquid and solids, using our special fine sieve and decanters. If there is no existing waste water plant and no space for a classical waste water treatment, the remaining water can be filtered to discharge standard, or even to high drinking standard by reverse osmosis technology.

Post treatment

10.The mechanical separated organic solids are dried by its internal biological power in our WTT intensive biological drying process.

11.The biofilter ensures that in the drying process steamed out water cause no smell pollution and releasing clean air.

12.A) After bio drying a fine screening remove remaining fine stones/glass. The dry organic fraction should be fertilizer from OFMSW. If not, like from MSW used as soft cover in landfills or can be incinerated.

B) All separated light fraction (plastics/close) from (6) go to our fine shredder (<60mm) produce green coal (RDF/SRF) with a good burning value 2200-2600 Kcal/kg. High energy production like cement- and steel-production can use this RDF to replace fossil coal contribute to less greenhouse gas emissions.

Advantages:

1."Urban Mining" starts with the separation the big waste streams into at least few reusable fractions: 1.Water, 2. RDF, 3. Biogas, 4. Metals, 5. Inerts.

2.The recovered biogas to operate the waste collection trucks with clean CO2 neutral fuel.

3.This solution can convert the light waste into green coal (RDF/SRF) 2500 Kcal = fossil coal useful for the high energy industry (Steel, Cement, Aluminum).

4.Flexible waste solution for the fast city development in China, prepared for mining more limited global resources.

5.Our MBT technology is very space efficient engineered to save China’s limited space and high value ground.

6.No toxic air pollution, No smell pollution, No hazardous fly ash.

7. We provide revolutionary 700% rise of energy recovery per ton MSW which is all renewable.

Example project in China: (“Reference” 1. Nanjing Jiangbei OFMSW project 2. Chongqing Luoqi OFMSW project)

Please contract us for a deeper talk about the best solution, considering well your regional condition of your project. Call +86 10 85323436

If you are interested to cooperate with us in your region, to develop commercial and technical supported by us waste projects together. Call +86 10 85323436